What Are Temperature Test Chambers?

In professional cosmetic product testing, temperature test chambers are one of the most important tools you will need to use. These test laboratories have controlled environments that help determine if products work well or not by using them to compare how long a product stays firm after being applied on your skin.

Temperature test chambers come in two main varieties: cold test chambers and hot test chambers. A cold test chamber uses refrigerated air to determine whether an ingredient works as intended by leaving its effect on the tested product for a set amount of time. A hot test chamber uses heated air to see just how quickly an ingredient fades.

There are different types of temperature test chambers depending on what element they contain and what type of test their users perform on the product. Some only do cold tests while others can also do hot ones! This article will go into more detail about both cool and warm test chambers and what each one is used for.

Types of temperature test chambers

A temperature test chamber is an insulated area where you can put material that you want to see if cools off or heats up more than normal depending on whether it is a heat-sensitive material or not.

There are several types of test equipment that use different temperature test chambers. Some are better than others, but they all work by observing changes in color, texture, or both. These observations are then correlated with information about the materials being tested to determine if it is susceptible to thermal exposure.

For example, leather will often get darker and tighter as it gets warmer. Melatonin powder will sometimes become slightly brighter in intensity when heated. The differences between these effects for each material usually stop there, however.

If you place one bag full of either product next to another similar bag, the effect would be lost because the products would disperse and possibly evaporate.

Cost of a temperature test chamber

The cost of having an accurate temperature reading comes down to what type of sensor you use, and how large your sample size is.

Temperature testing can easily run in the hundreds or even thousands depending on the accuracy needed and the volume of samples being tested.

The price per test will vary due to these factors as well as the company that you choose to work with. Some companies offer freebies such as using their equipment and sensors, so make sure to look out for those!

We recommend trying out their equipment before buying it since they may give you a loaner device or two. This way you get to experience the quality of their products first!

General tools like thermal cameras and infrared thermometers are very affordable, usually less than $100 each. For more advanced equipment such as heat gun probes and external resistance thermometers (ERTs), the prices become slightly higher but still within a reasonable range.

Sample test

A temperature test is one of several tests that are used to determine if there is copper in your water. These include acid, alkali, heat, and dispersion testing. Acid and alkaline reactions require professional help to perform so they are not done at home!

Acid testing for copper uses vinegar as the reagent. You mix an amount of vinegar with a known concentration of zinc (or sodium) powder and then add distilled water until the mixture has the right consistency. Then you put some of the solution onto a glass plate and wait for the color to develop. The longer it takes for a color to appear, the more copper there is in the sample.

Alkaline testing requires using potassium hydroxide (KOH) liquid as the reagent. Just like with the acid test, you make sure the KOH fluid is mixed well and then apply it to a solid surface. If it reacts quickly, there may be too much copper in the water.

Heating up a sample of water or leaving the water open where it can evaporate will cause the ions in the water to separate. When this happens, there are no longer clusters of copper particles interacting with other materials. This creates an inaccurate result because there is no way to tell whether there is still trace amounts of copper in the water or not.

Dispersion methods use special filters to isolate individual atoms of copper.

Tips for a good temperature test chamber

First, you want to make sure your temperature test chamber is properly insulated. This will prevent heat loss or gain from affecting the temperatures measured by the equipment.

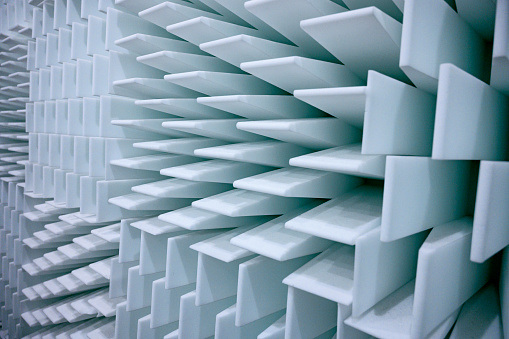

You can buy thermal insulation that are made of foam (the most common type being polyurethane foam). These are usually cut into various shapes such as squares or rectangles.

By adding these sheets in between the test specimen and the tube that carries away the excess heat, you increase the effective insulating layer. You also need to ensure there are no holes or exposed surfaces that could let some of the heat escape.

Temperature test chambers should be completely enclosed so that any moisture in the air cannot affect the results.

Tips for creating a test environment

A temperature test chamber is one of the most important tools in ensuring the best possible thermal readings from your meter. While some manufacturers include a white box or cover to hold the sensor close to heat sources, this is not practical when doing actual testing.

A better solution is to create an insulated container that can be heated or cooled as needed. This way, the sensor has direct exposure to all heat sources, but also remains cool enough to give accurate results.

There are many ways to do this, but our favorite method uses two empty soda cans! Here’s what we like to do.

Research your testing conditions

The last thing you want to do is test your product under wrong conditions that may not be representative of real world use. Different temperature test chambers have their own specifications and limitations, so it is very important to know what each one is before using them for tests.

You should always check out the manufacturer’s website and/or talk to someone who has used one before in order to make sure this set up is right for your products. Some companies will even send you the correct equipment free!

There are many different types of test environments, but all require a source of heat or cold. These sources can be natural warm air (like an oven) or cooled gases (such as dry ice or liquid nitrogen), solid materials such as blocks of frozen water or alcohol, heated plastics, and more.

Some people combine several methods together in order to achieve the most accurate results. However, there is no “best” way to test temperatures unless the test environment does not contain enough heat or cold to prevent your sample from functioning correctly.

Update your testing equipment

The second major factor in having accurate results is choosing the right test equipment. There are many different types of temperature test chambers, and it can be confusing which one you should use!

Temperature controlled environmental test chambers come in two main styles: cold chamber tests and hot chamber tests. A cold chamber test uses a cooling device to reduce heat coming from the material being tested, while a hot chamber test adds heat to determine if the material conducts or not.

It is important to know what kind of materials your product will contact, whether they are plastic, metal, or rubber, and how these changing temperatures affect the material. Some plastics melt at high temperatures, some conduct electricity, and some do both. Therefore, by using an appropriate test environment, we can learn more about the material’s properties.